Watch heads, straps, movements: the TIMELAB laboratory tests, analyzes, and controls all components of a timepiece in various contexts corresponding to their lifecycle (resistance, aging, water resistance, magnetism, etc.). Testing follows standard norms or personalized protocols.

As a holder of international accreditations, the laboratory collaborates closely with universities and higher education institutions. This privileged access provides brands with additional scientific expertise and the opportunity to explore new avenues under the supervision of the TIMELAB team.

Thanks to its versatile equipment, TIMELAB is capable of testing numerous other products and industrial instruments (jewelry, medical devices, etc.). Some tests can be conducted directly at the brands' premises.

TIMELAB plays a crucial role between different phases of research, certification, development, manufacturing, production, and after-sales service. Its multidisciplinary experts provide comprehensive reports (including intermediate test results), improvement suggestions, and complete solutions for product development.

Chronometric measurements for "Chronometer" certification or characterization purposes.

Acceleration of the watch's lifecycle to characterize its level of reliability and robustness.

Tests to simulate the specific environments that a watch may encounter throughout its lifecycle.

Acceleration of the bracelet's lifecycle and mechanical characterization.

Control of the watch's behavior when exposed to everyday magnetic sources.

Control of the watch's water resistance according to its maximum specifications.

Simulation of the accelerations and impacts that the watch will experience during its lifecycle.

Characterization of the watch's acoustics, particularly for minute repeaters.

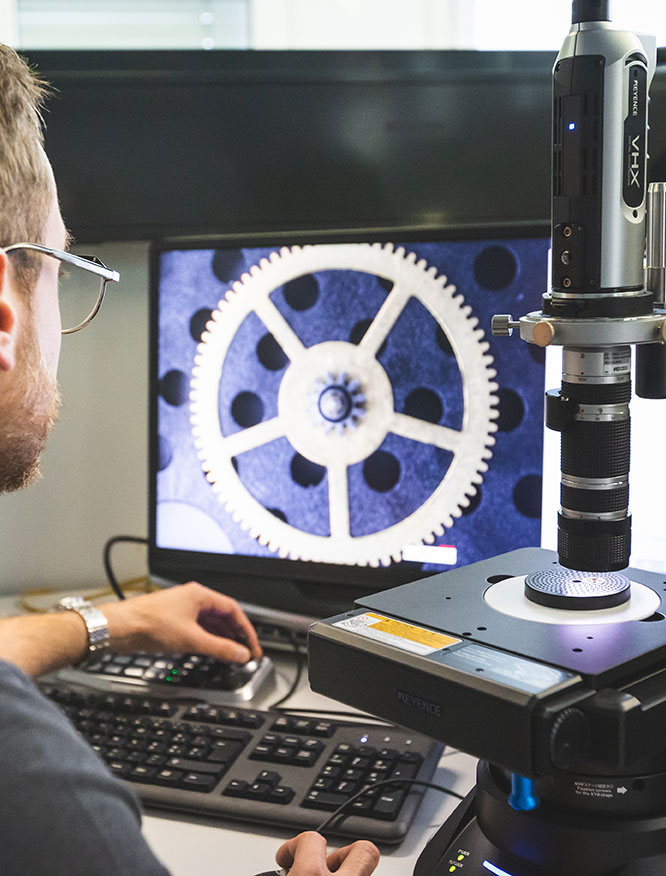

Mechanical characterization of the watch's components.